Piezo ceramics as cutting head drivers?

Moderators: piaptk, tragwag, Steve E., Aussie0zborn

Piezo ceramics as cutting head drivers?

Hi all,

Has anyone here played with PZT stacks as a driver for a cutter?

I am thinking in terms of something like a pair of ThorLabs PZS001 in push/pull (to cancel the (significant) hysteresis and make applying preload easier), with the control loop closed by the strain gauges.

The upside is that these things produce a LOT of force, but not a lot of deflection, and they are stiff so even when pushing a fairly large mass the resonance stays high.

They do not survive tension well so preload will be required and they are annoyingly capacitive, so if driving from a conventional amplifier stability may be an issue. The solution here is probably to minimise the amplifier internal electrical feedback and go for closing the loop around the whole thing with the strain gauges.

Kemet seem to have viable parts as well, but mousers prices for those are worse then thorlabs! Morgan electro ceramics might have something, has anyone done anything with this sort of thing?

Regards, Dan.

Has anyone here played with PZT stacks as a driver for a cutter?

I am thinking in terms of something like a pair of ThorLabs PZS001 in push/pull (to cancel the (significant) hysteresis and make applying preload easier), with the control loop closed by the strain gauges.

The upside is that these things produce a LOT of force, but not a lot of deflection, and they are stiff so even when pushing a fairly large mass the resonance stays high.

They do not survive tension well so preload will be required and they are annoyingly capacitive, so if driving from a conventional amplifier stability may be an issue. The solution here is probably to minimise the amplifier internal electrical feedback and go for closing the loop around the whole thing with the strain gauges.

Kemet seem to have viable parts as well, but mousers prices for those are worse then thorlabs! Morgan electro ceramics might have something, has anyone done anything with this sort of thing?

Regards, Dan.

Re: Piezo ceramics as cutting head drivers?

Starting with a speaker severely limits your design options. For example, it forces a much larger overall head body to accommodate the speaker element. Another example is the fact that you have to mate to the diaphragm which presents issues and is not mechanically efficient. Third is the lack of a controllable tension on the transducer to allow highs to shine.

For anyone who wants to DIY a cutterhead I offer custom coil service. I can be contracted to make either drive or feedback coils of any variety: form or formless, flattened enameled wire or standard, 26 gauge to 46 gauge. Any size or dimensions you like. Choice of materials for bobbins. Or, as stated, I can make bobbinless air coils. Food for thought. PM me for details if interested.

For anyone who wants to DIY a cutterhead I offer custom coil service. I can be contracted to make either drive or feedback coils of any variety: form or formless, flattened enameled wire or standard, 26 gauge to 46 gauge. Any size or dimensions you like. Choice of materials for bobbins. Or, as stated, I can make bobbinless air coils. Food for thought. PM me for details if interested.

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Re: Piezo ceramics as cutting head drivers?

Which would be why I was suggesting NOT using classical magnetic motors at all might be a worthwhile avenue to explore!

I know the classic way to do it, and I know 'crystal' cutting heads were in general crap, but it seems to me that 30 odd years of technology improvements might have made at least as much difference to PZT type ceramics as it has made to magnets (The materials science is not a million miles apart).

If it comes to that, has anyone tried something using a magneto-restrictive material (eg Terfenol-D or similar)?

Regards, Dan.

I know the classic way to do it, and I know 'crystal' cutting heads were in general crap, but it seems to me that 30 odd years of technology improvements might have made at least as much difference to PZT type ceramics as it has made to magnets (The materials science is not a million miles apart).

If it comes to that, has anyone tried something using a magneto-restrictive material (eg Terfenol-D or similar)?

Regards, Dan.

Re: Piezo ceramics as cutting head drivers?

Good luck with that!

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Re: Piezo ceramics as cutting head drivers?

Oh I am quite prepared to believe it won't work, but any chance of a few words about why not?

You got to figure on getting the null result about 95 times out of a 100 when experimenting with stuff, but if you have been down this rabbit hole and found a dead end, please explain, if only to save me going to the same place and having to back up.

Magnetorestrictive drivers are a thing (usually aimed at the novelty 'turn anything into a speaker' market, but they exist), and those ceramics with the built in strain gauge seem workable to me (if a little expensive).

Regards, Dan.

You got to figure on getting the null result about 95 times out of a 100 when experimenting with stuff, but if you have been down this rabbit hole and found a dead end, please explain, if only to save me going to the same place and having to back up.

Magnetorestrictive drivers are a thing (usually aimed at the novelty 'turn anything into a speaker' market, but they exist), and those ceramics with the built in strain gauge seem workable to me (if a little expensive).

Regards, Dan.

Re: Piezo ceramics as cutting head drivers?

I have my opinions which are formed from experience. Regardless of that experience, you should tinker. Its the only way you can start to bridge from hypothetical/academia to real world results. I encourage everyone to try things no matter how much they may or may not make sense. Not making sense sometimes doesn't mean not reality, its you perspective that gets in the way....

Beyond that, my immediate reaction is how accurate is that gauge? If you're basing a feedback system on an inaccurate or delayed sensor it goes from being a corrective factor to being a destructive one. I.e. if you're feedback isn't pristine and as immediate as possible then negative feedback summing can quickly turn to positive feedback summing, which is noise.

Beyond that, my immediate reaction is how accurate is that gauge? If you're basing a feedback system on an inaccurate or delayed sensor it goes from being a corrective factor to being a destructive one. I.e. if you're feedback isn't pristine and as immediate as possible then negative feedback summing can quickly turn to positive feedback summing, which is noise.

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Re: Piezo ceramics as cutting head drivers?

Well aware of the effect of phase shifts on loop stability, this is control theory 101 (And probably why most feedback heads had to limit the bandwidth of the feedback loop to avoid oscillation)....

It is the location of those gauges that concerns me far more then the ability of the things to work, they are on the driver not the business end of the cutter, so will be unable to compensate the resonances in the mechanics between the drivers and the cutter. Some capacitive pickup is possible I suppose, but if need be they can be run at a few hundred kHz excitation and synchronously demodulated to remove the audio band coupling.

Might need to be dual loop, one inner one to linearize the drivers and an outer loop to control the imperfections in the structure between the drive and the cutting stylus or even do the inner thing semi open loop with a least-mean-squared curve fitter in DSP?

Lots of things you can do today that were not possible in the 1950s.

I think I am going to give it a go, sure probably won't work, but I WILL learn something!

It is the location of those gauges that concerns me far more then the ability of the things to work, they are on the driver not the business end of the cutter, so will be unable to compensate the resonances in the mechanics between the drivers and the cutter. Some capacitive pickup is possible I suppose, but if need be they can be run at a few hundred kHz excitation and synchronously demodulated to remove the audio band coupling.

Might need to be dual loop, one inner one to linearize the drivers and an outer loop to control the imperfections in the structure between the drive and the cutting stylus or even do the inner thing semi open loop with a least-mean-squared curve fitter in DSP?

Lots of things you can do today that were not possible in the 1950s.

I think I am going to give it a go, sure probably won't work, but I WILL learn something!

Re: Piezo ceramics as cutting head drivers?

Have you actually seen my work? I need no instructions. But, thanks.

Dual feedback loop sounds like a huge hack. And, prone to false data. Also, sounds like more space to account for.

My professional stereo feedback cutterhead contains no speakers and is smaller than a Neuman SX cutterhead. So, yeah, I'm familiar with modernization.

Voice coils for drive and feedback are still king IMHO.

Dual feedback loop sounds like a huge hack. And, prone to false data. Also, sounds like more space to account for.

My professional stereo feedback cutterhead contains no speakers and is smaller than a Neuman SX cutterhead. So, yeah, I'm familiar with modernization.

Voice coils for drive and feedback are still king IMHO.

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Re: Piezo ceramics as cutting head drivers?

Voice coils are the way to go if you are looking to build a product rather then play in the lab, that is certainly true as it is tried and tested technology so the problem is one of engineering a design that works with modern bits and hits a target BOM cost.

However my interest is in the exploration of the odd corners of the technology, rather then producing a commercial head design.

I find interest in exploring all the things that could (but probably won't) work in pursuit of the 5% or so that do actually work (And the 0.05% or so that are an improvement). Research not Development (I do enough of that in the day job).

Dual feedback loops are actually pretty mundane, the trick being to make the inner loop have rather more bandwidth then the outer one so there is sufficient phase margin in the outer loop. I have ways to measure loop phase margin so not too worried about putting the poles and zeros in the right places.

Parts are on order for (initially) a mono cutter initially without feedback to test the general feasibility of the idea (Mono because I only need half the number of driver elements, half the signal processing and half the drive amps), it will relatively easily disprove the point when it don't work, but I will have learned something.

Irrespective of the driver, strain gauges for feedback are an interesting thought IMHO but I cannot actually find any documentation on the effective bandwidth of the things, which is weird, time for an experiment I guess

If I just wanted to buy a head and cut disks, your product would be a serious contender, but that is not quite where I am coming from.

Regards, Dan.

However my interest is in the exploration of the odd corners of the technology, rather then producing a commercial head design.

I find interest in exploring all the things that could (but probably won't) work in pursuit of the 5% or so that do actually work (And the 0.05% or so that are an improvement). Research not Development (I do enough of that in the day job).

Dual feedback loops are actually pretty mundane, the trick being to make the inner loop have rather more bandwidth then the outer one so there is sufficient phase margin in the outer loop. I have ways to measure loop phase margin so not too worried about putting the poles and zeros in the right places.

Parts are on order for (initially) a mono cutter initially without feedback to test the general feasibility of the idea (Mono because I only need half the number of driver elements, half the signal processing and half the drive amps), it will relatively easily disprove the point when it don't work, but I will have learned something.

Irrespective of the driver, strain gauges for feedback are an interesting thought IMHO but I cannot actually find any documentation on the effective bandwidth of the things, which is weird, time for an experiment I guess

If I just wanted to buy a head and cut disks, your product would be a serious contender, but that is not quite where I am coming from.

Regards, Dan.

Re: Piezo ceramics as cutting head drivers?

Hi Dan,

Sounds like an interesting project. I believe Gib is rebuilding old crystal cutters using modern PZT elements, so what you are proposing to do should be possible. Do you think you can get +/- 150 um of excursion directly or will you have to employ a lever to amplify the motion? What did you end up ordering as your PZT element? I had thought of harvesting the element from a grill igniter.

On the strain gauge front, I think you will be ok as far as bandwidth goes as I don't see any electrical reason that they would be limited. There were phono pickups that were based on strain gauges back in the day. They had very good performance and are still sought after. The load cells I've used are low impedance and I was able to get 100000:1 resolution but the bandwidth was much lower than you need (about 100 hz). I would be concerned that the strain gauge might have issues with pickup of the drive signal, especially at high frequencies. You might have to resort to a an AC mod/demod method for the strain gauge bridge to filter out the baseband drive signal.

You seem to have the technical skill set needed to pull this off. I hope you let us know how the experiment goes.

Good luck,

Mark

Sounds like an interesting project. I believe Gib is rebuilding old crystal cutters using modern PZT elements, so what you are proposing to do should be possible. Do you think you can get +/- 150 um of excursion directly or will you have to employ a lever to amplify the motion? What did you end up ordering as your PZT element? I had thought of harvesting the element from a grill igniter.

On the strain gauge front, I think you will be ok as far as bandwidth goes as I don't see any electrical reason that they would be limited. There were phono pickups that were based on strain gauges back in the day. They had very good performance and are still sought after. The load cells I've used are low impedance and I was able to get 100000:1 resolution but the bandwidth was much lower than you need (about 100 hz). I would be concerned that the strain gauge might have issues with pickup of the drive signal, especially at high frequencies. You might have to resort to a an AC mod/demod method for the strain gauge bridge to filter out the baseband drive signal.

You seem to have the technical skill set needed to pull this off. I hope you let us know how the experiment goes.

Good luck,

Mark

Re: Piezo ceramics as cutting head drivers?

It is going to have to be a leaver or something of that sort to get anything like that much excursion (There are some tricks sonar used to do that may be applicable, but it is annoyingly small bits of metal to fabricate such things).

Gas lighter elements probably won't work, I was thinking more in terms of the Thorlabs or Kemet parts, maybe build a tonpils style stack out of disks from Morgan?

What would be helpful would be pre polled elements as that avoids the need for a standing DC bias voltage, but those seem to be annoyingly specialist (We used these routinely in sonar applications).

RF somewhere below 1MHz and a synchronous demodulator (Probably based on some form of H mode mixer) seems likely to be the thing for the gauges, but I have been wondering about a capacitive sensor as an alternative.

Yea, there will be pictures, if only as a 'don't go here' warning to others.

Gas lighter elements probably won't work, I was thinking more in terms of the Thorlabs or Kemet parts, maybe build a tonpils style stack out of disks from Morgan?

What would be helpful would be pre polled elements as that avoids the need for a standing DC bias voltage, but those seem to be annoyingly specialist (We used these routinely in sonar applications).

RF somewhere below 1MHz and a synchronous demodulator (Probably based on some form of H mode mixer) seems likely to be the thing for the gauges, but I have been wondering about a capacitive sensor as an alternative.

Yea, there will be pictures, if only as a 'don't go here' warning to others.

Re: Piezo ceramics as cutting head drivers?

I was a piezo engineer in a former career.

Off the hip, I'd look into flexure based amplification frames. PiezoDrive sells them as AP Series Amplified Piezo Actuators and Dynamic Materials and Structures sells them as FPA. This style of actuator is easy to manufacture and the patent's are expired, so they are relatively common. Unfortunately, the resonance peaks for these devices are low. As you can see on the PiezoDrive website, the AP350 has the +/- stroke we need with a 350 um range, but the resonance is only 480 Hz. If we were to cut out low end under 1k hz, this might be fine, but its certainly not something I would consider investing the time and effort into if I didn't already have $5k-$10k worth of piezo actuators and amps laying around.

Bare stakes will give you roughly 1.5% strain. So a 300um range would require a 200mm stack ( or four 50mm stacks....stacked...together). You'd still need to have them in a compression frame to keep the stacks from going into tension during operation. But this would be something custom like the "Compact Piezo Actuator for Cryogenic Isolation Valve(s)", as shown on the DSM "custom" page on their website. Personally, the largest such actuator I've ever designed/built was a 150mm unit for CERN. That was a BIG actuator. Definitely not something that you could mount on the end of a normal turntable arm.

But this all assumes required travel of the needle is the required displacement of the actuator.... If the needle pivots about a center of rotation, that should give us some level of gain so the actuator only needs to have a stroke that is some fraction of required needle cutting tip displacement.

I'm game for pulling something out of my old project boxes if we can think of a setup that might give decent performance in a form factor that doesn't require fabricating a new arms/linear stage just to mount the cutter. Maybe a rotatory stage that's actually mounted at the center of rotation for the armature.....

Off the hip, I'd look into flexure based amplification frames. PiezoDrive sells them as AP Series Amplified Piezo Actuators and Dynamic Materials and Structures sells them as FPA. This style of actuator is easy to manufacture and the patent's are expired, so they are relatively common. Unfortunately, the resonance peaks for these devices are low. As you can see on the PiezoDrive website, the AP350 has the +/- stroke we need with a 350 um range, but the resonance is only 480 Hz. If we were to cut out low end under 1k hz, this might be fine, but its certainly not something I would consider investing the time and effort into if I didn't already have $5k-$10k worth of piezo actuators and amps laying around.

Bare stakes will give you roughly 1.5% strain. So a 300um range would require a 200mm stack ( or four 50mm stacks....stacked...together). You'd still need to have them in a compression frame to keep the stacks from going into tension during operation. But this would be something custom like the "Compact Piezo Actuator for Cryogenic Isolation Valve(s)", as shown on the DSM "custom" page on their website. Personally, the largest such actuator I've ever designed/built was a 150mm unit for CERN. That was a BIG actuator. Definitely not something that you could mount on the end of a normal turntable arm.

But this all assumes required travel of the needle is the required displacement of the actuator.... If the needle pivots about a center of rotation, that should give us some level of gain so the actuator only needs to have a stroke that is some fraction of required needle cutting tip displacement.

I'm game for pulling something out of my old project boxes if we can think of a setup that might give decent performance in a form factor that doesn't require fabricating a new arms/linear stage just to mount the cutter. Maybe a rotatory stage that's actually mounted at the center of rotation for the armature.....

Re: Piezo ceramics as cutting head drivers?

Hi,

480 Hz is not too bad given that the typical moving coil head main resonance sits in the 1-2 Khz range. In fact, that matches up pretty closely with the IRIAA turnover that is specified at 500hz so you get the first half of the RIAA for free. If the actuator falls off nicely at -12dB/oct above resonance and is well damped, it should make a nice driver. You would only need the IRIAA 50 and 2122 Hz boosts to EQ the head. Some questions are: how expensive is this actuator and what kind of electrical drive does it require? I'm sure its a mostly a pure capacitive load.

Mark

480 Hz is not too bad given that the typical moving coil head main resonance sits in the 1-2 Khz range. In fact, that matches up pretty closely with the IRIAA turnover that is specified at 500hz so you get the first half of the RIAA for free. If the actuator falls off nicely at -12dB/oct above resonance and is well damped, it should make a nice driver. You would only need the IRIAA 50 and 2122 Hz boosts to EQ the head. Some questions are: how expensive is this actuator and what kind of electrical drive does it require? I'm sure its a mostly a pure capacitive load.

Mark

Re: Piezo ceramics as cutting head drivers?

I was thinking a flexture mount water jet cut out of steel, with two elements for each channel in push/pull (Ok, really push/push, but you know what I mean) to cancel the hysteresis. The devices produce massive forces compared to any voice coil so a flexture leaver system should work. Might be able to might a flexture that is stiff enough in the other axis to avoid the need for a torque tube?

A poke around the Thorlabs site shows what is possible in this line, but sadly they do not seem to offer the two devices preloaded and driven in anti phase that I would want.

The things are basically lossy capacitive loads, so we would need an amp that is not too bothered by a seriously leading load angle.

I am currently deep in other things, so finding the time to play with this bit may have to wait a while for me.

A poke around the Thorlabs site shows what is possible in this line, but sadly they do not seem to offer the two devices preloaded and driven in anti phase that I would want.

The things are basically lossy capacitive loads, so we would need an amp that is not too bothered by a seriously leading load angle.

I am currently deep in other things, so finding the time to play with this bit may have to wait a while for me.

- circitfied

- Posts: 17

- Joined: Tue Nov 03, 2015 11:18 am

Re: Piezo ceramics as cutting head drivers?

I was looking at using piezo's in my research too.

I was worried about stacking piezo's and not having them aligned correctly, so that there could be some form of rotational errors too. However, from what the expert above says, that may not be a problem.

I have one of the Thorlabs units on the side.

I really like the idea of directly coupling a piezo stack to a cutting stylus, amplitude could be controlled by selectively firing off individual piezo's. Especially if you had 200mm of them.

I was worried about stacking piezo's and not having them aligned correctly, so that there could be some form of rotational errors too. However, from what the expert above says, that may not be a problem.

I have one of the Thorlabs units on the side.

I really like the idea of directly coupling a piezo stack to a cutting stylus, amplitude could be controlled by selectively firing off individual piezo's. Especially if you had 200mm of them.

Re: Piezo ceramics as cutting head drivers?

Just drive them with a power amp, no need to think pulses here.

- grooveguy

- Posts: 432

- Joined: Thu Jun 22, 2006 5:49 pm

- Location: Brea, California (a few miles from Disneyland)

- Contact:

Re: Piezo ceramics as cutting head drivers?

Interesting thread, Dan. Piezo actuators actually did work pretty well in the suitcase cutters of the 1940s, and Shure had a professional cutterhead (RC20 if memory serves) that gave quite commendable performance as long as the room temperature was livable. Recently I've looked into some TDK piezo transducers that seemed to hold promise, although they'd need some aftermarket leverage to move a stylus tip ±.005". Gib guards his head rebuilding trade secrets well, but I've seen the innards of one of his rebuilds, and it's certainly not rocket science, though I'd like to know his source for actuators. Do please pursue this and keep us informed of any progress... or lack of. Lots of good resources on this group.

Re: Piezo ceramics as cutting head drivers?

Hi, Maybe it is possible to use a piezo stacks from automotive piezo injectors, or maybe just cutted/modified injectors as direct/lever drivers. Used one can cost 30 dollars

- grooveguy

- Posts: 432

- Joined: Thu Jun 22, 2006 5:49 pm

- Location: Brea, California (a few miles from Disneyland)

- Contact:

Re: Piezo ceramics as cutting head drivers?

That's a thought, although I have no idea how injectors work. If it's multiple pulses of fuel in small increments in a given time space, that would work for something relatively slow, like an automobile engine, but we need to move several thou at an audio rate, out to 15kHz. Certainly worth looking into, though.

Re: Piezo ceramics as cutting head drivers?

Unfortunately also don't know exactly how they work. I once found out about them by the way, when I was looking for jetting valves for jet printing solder paste.

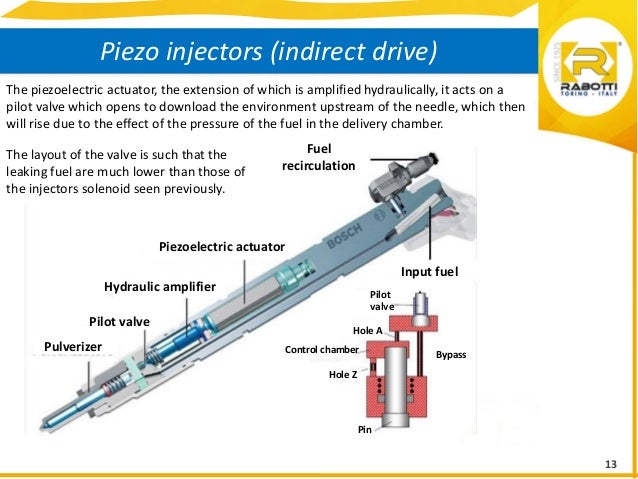

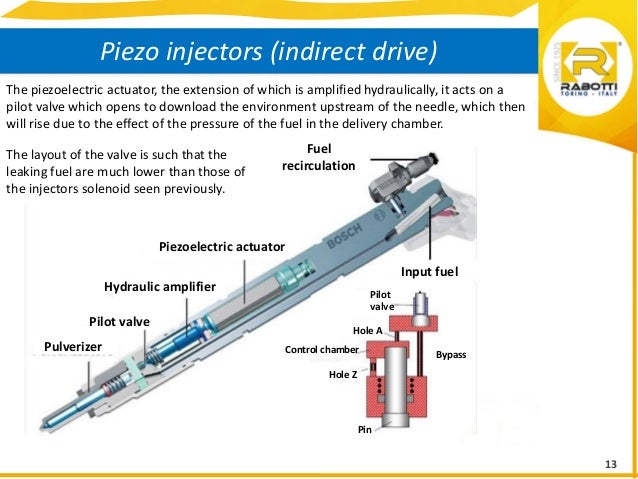

There are two varieties; the indirect one (with shorter piezo stack + chydraulic motion amplifier) and the direct one with a longer piezo stack (there is a mechanical lever here too, but maybe this vary from model or manufacturer). To power the direct ones, there is need for 160-200V and 5A(?) in peak.

Found some two images from https://www.slideshare.net/LucaNurchi/introduction-to-common-rail (slides 14 and 15).

I'm not sure if only Delphi produces direct models. The example model is probably Delphi 28254952.

I wonder how they sound (if they sound at all) after connecting to some PA amplifier (100V output, but it may not be enough).

There are two varieties; the indirect one (with shorter piezo stack + chydraulic motion amplifier) and the direct one with a longer piezo stack (there is a mechanical lever here too, but maybe this vary from model or manufacturer). To power the direct ones, there is need for 160-200V and 5A(?) in peak.

Found some two images from https://www.slideshare.net/LucaNurchi/introduction-to-common-rail (slides 14 and 15).

I'm not sure if only Delphi produces direct models. The example model is probably Delphi 28254952.

I wonder how they sound (if they sound at all) after connecting to some PA amplifier (100V output, but it may not be enough).