I used to make needles with a jig but you're limited to one geometry.

Now that I got used to using the tool & cutter grinder for making embossing cones I thought I'd use it for needles too.

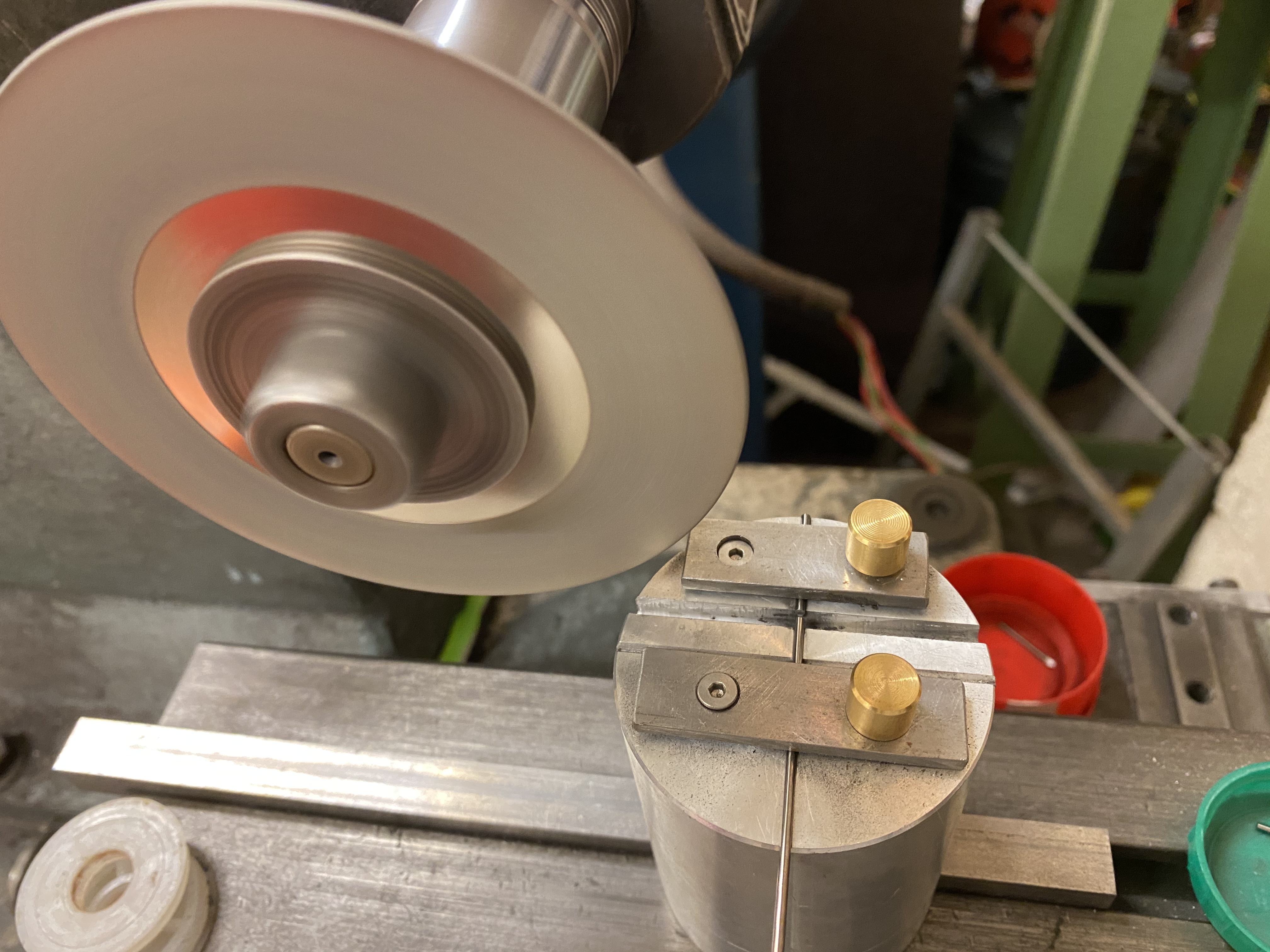

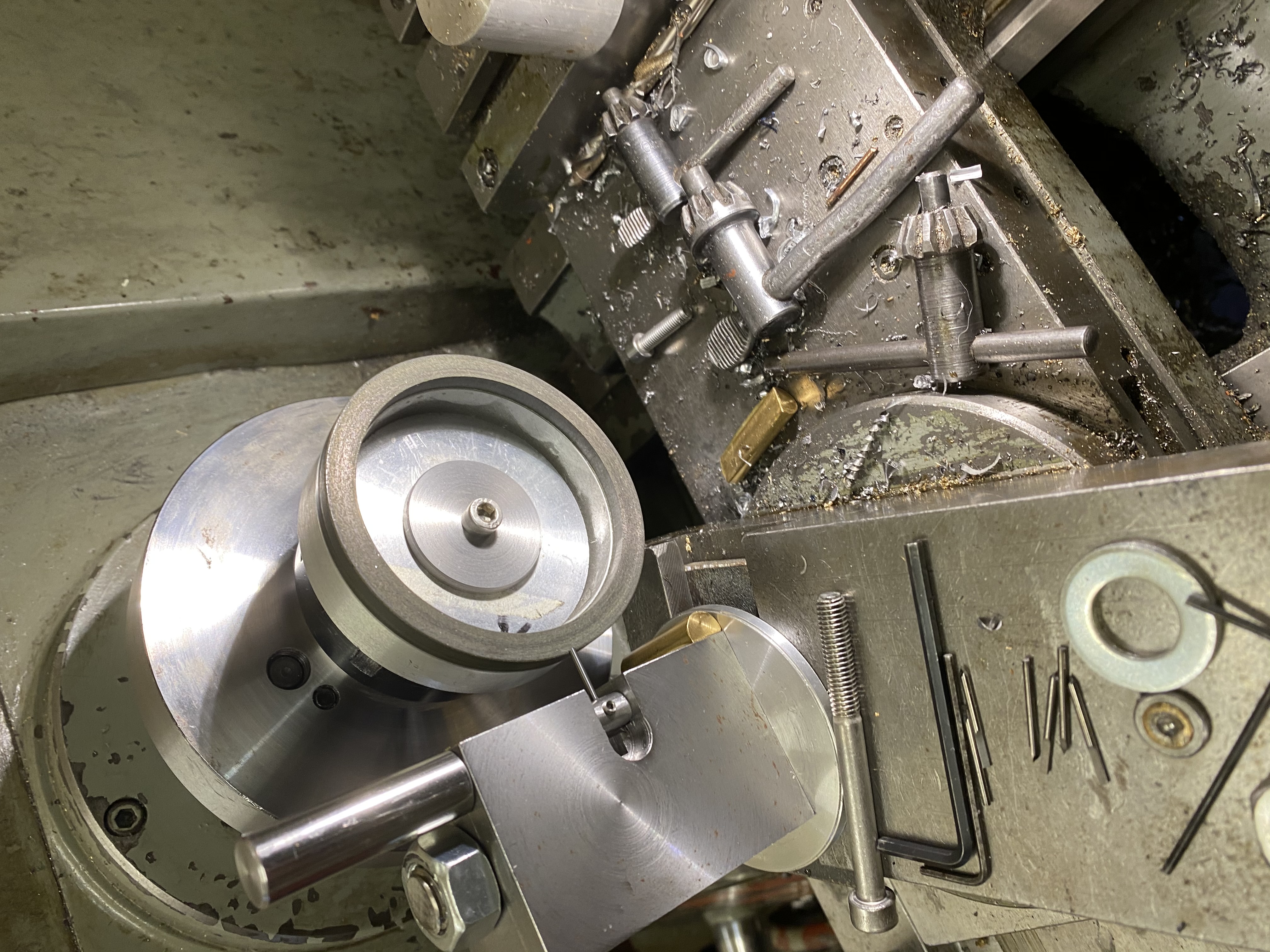

Step 1: Parting off on the Clarkson T&C grinder

Step 2: Cutting the locating face on the Tiplap T&C grinder

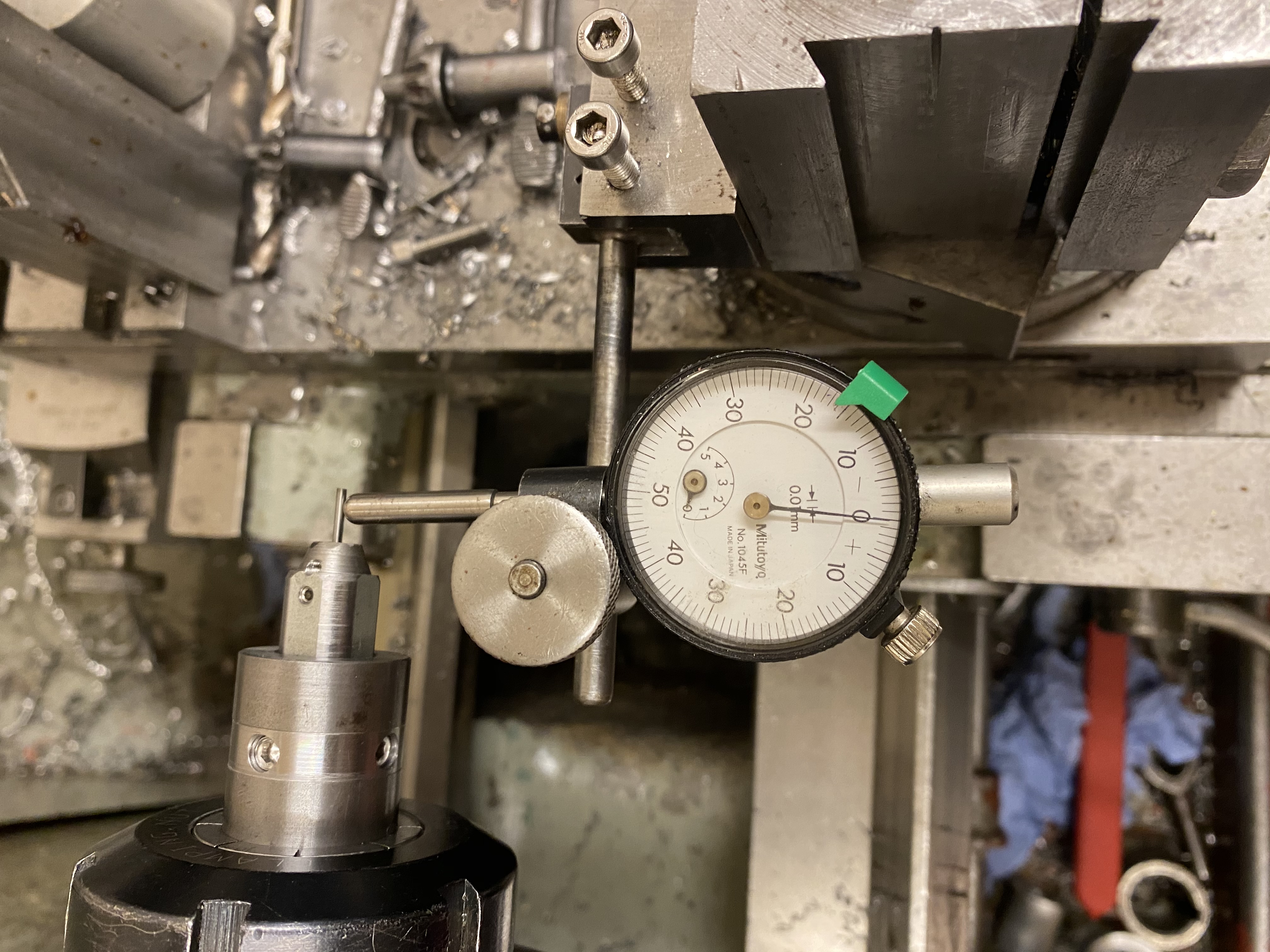

Step 3: Clocking the needle in the holder (Colchester Bantam lathe).

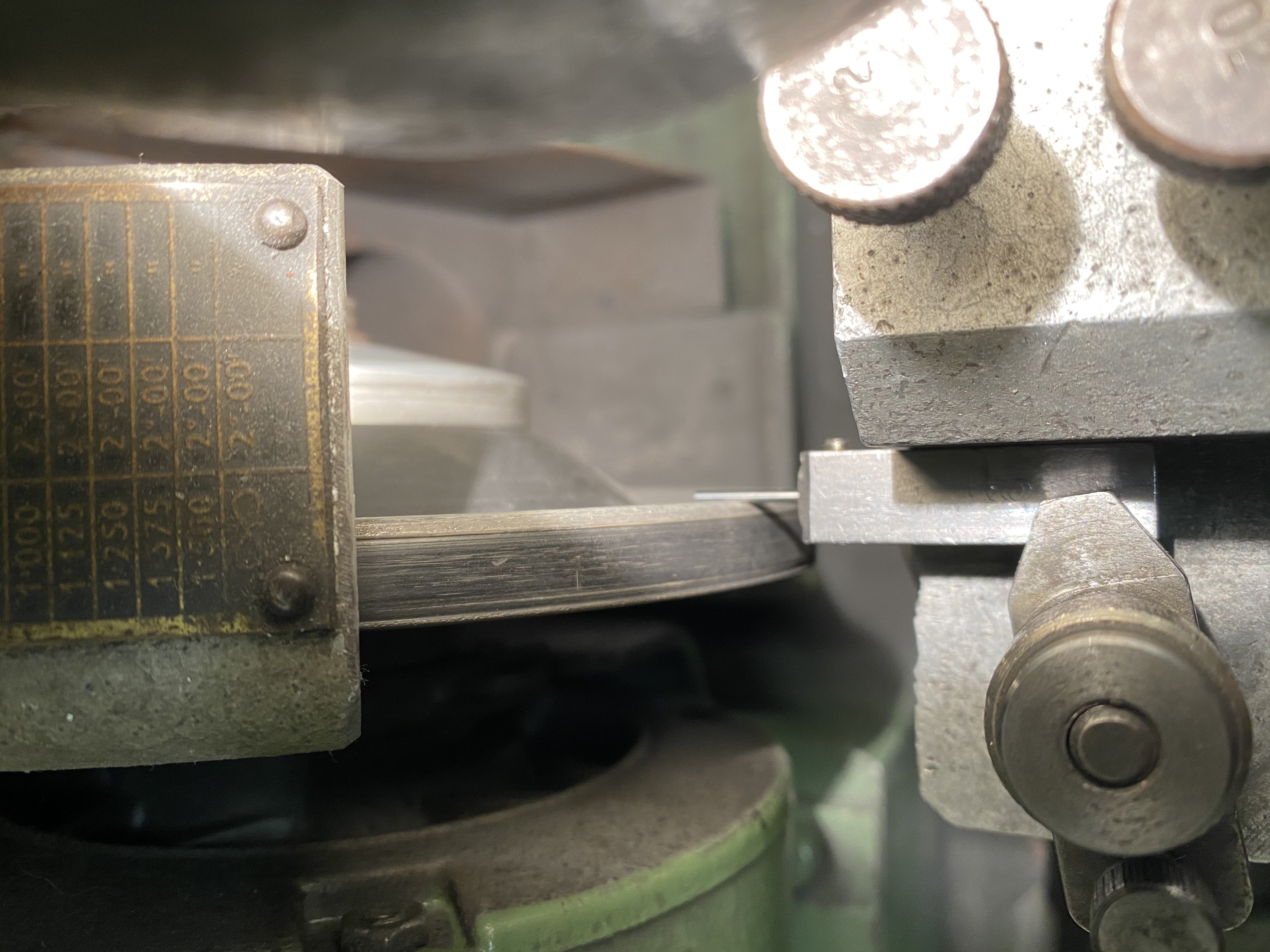

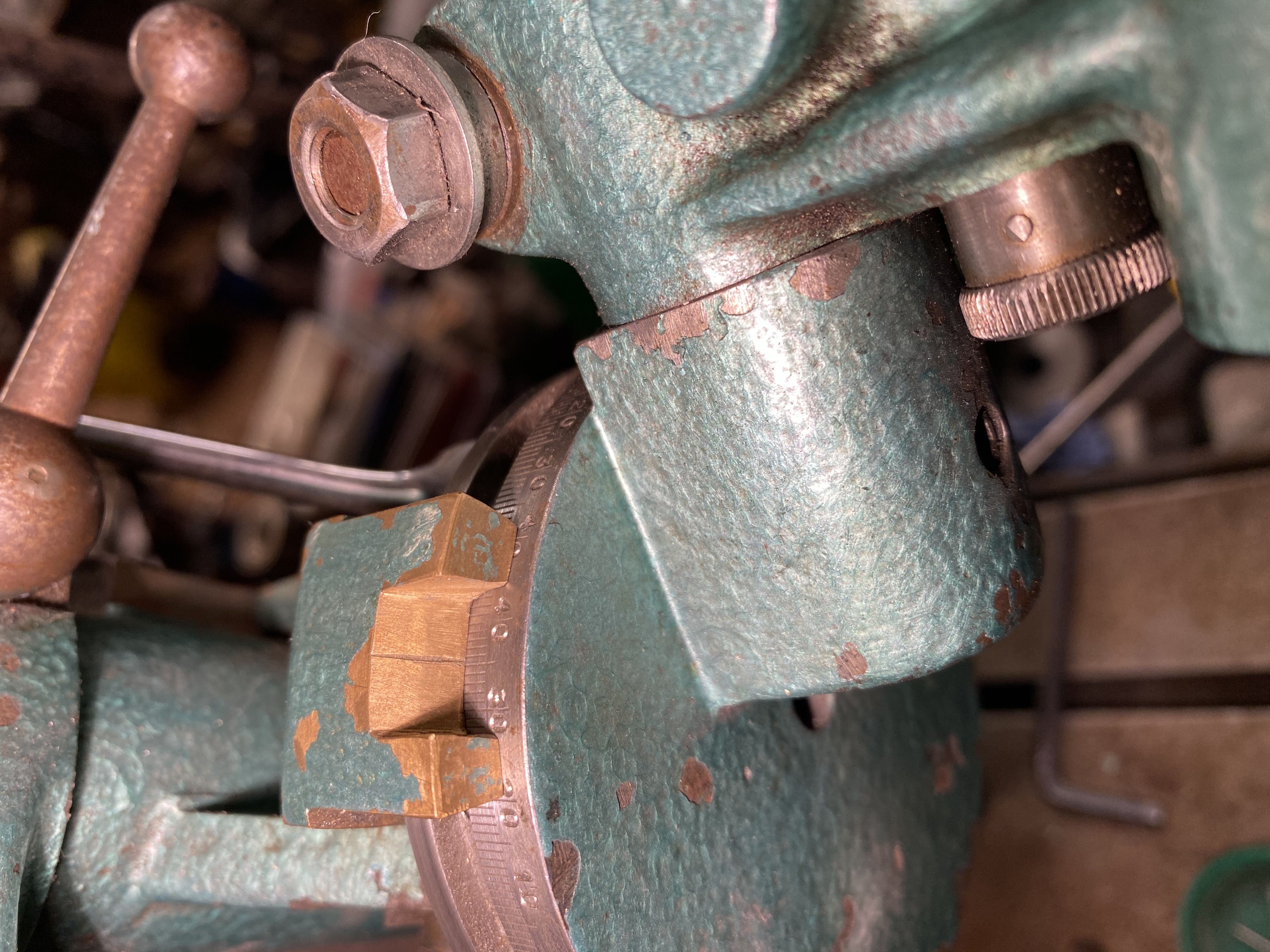

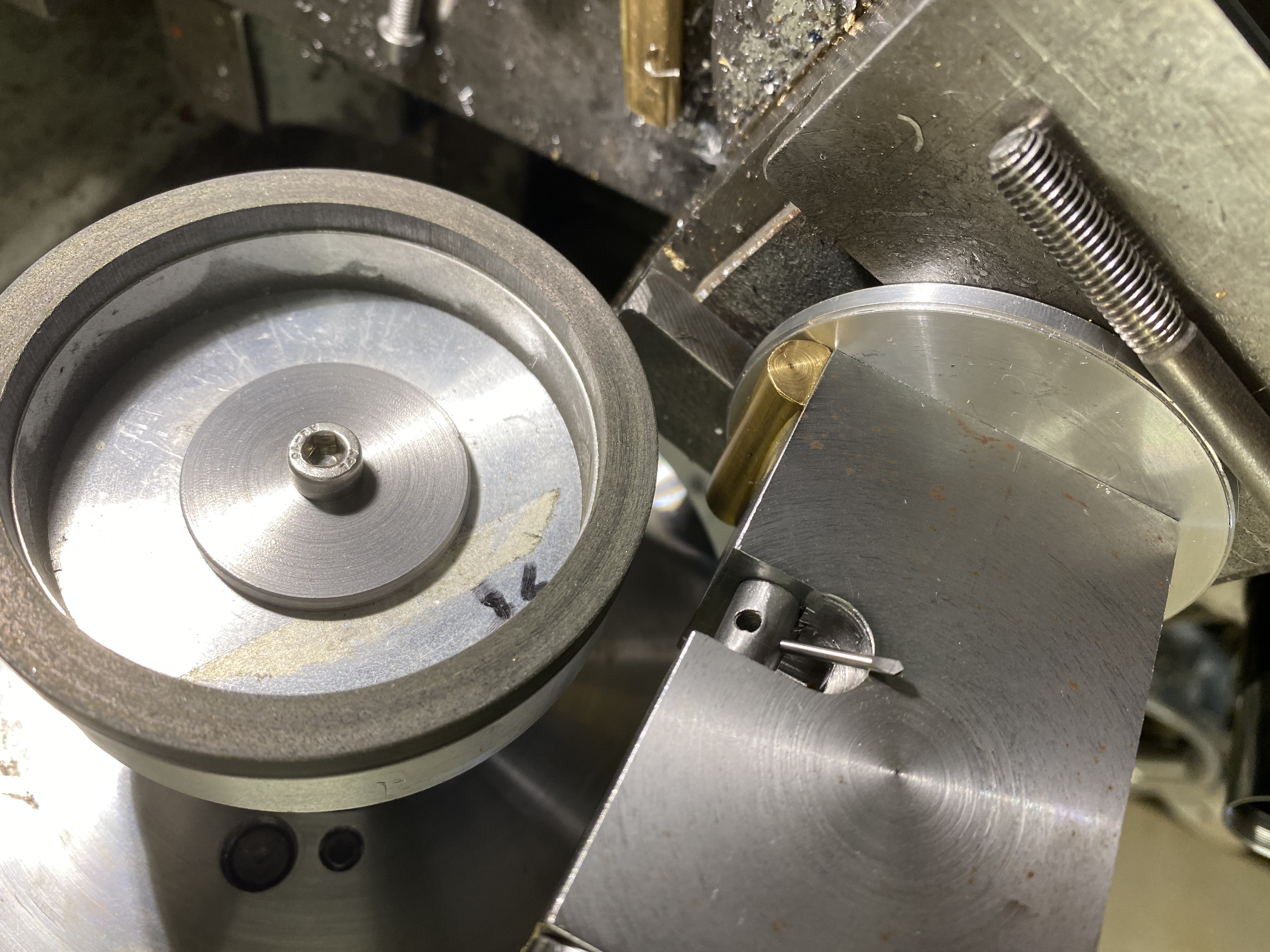

Step 4: Setting the face angle. Here to 35.5 degrees for a full angle of 71 degrees (Quorn T&C grinder).

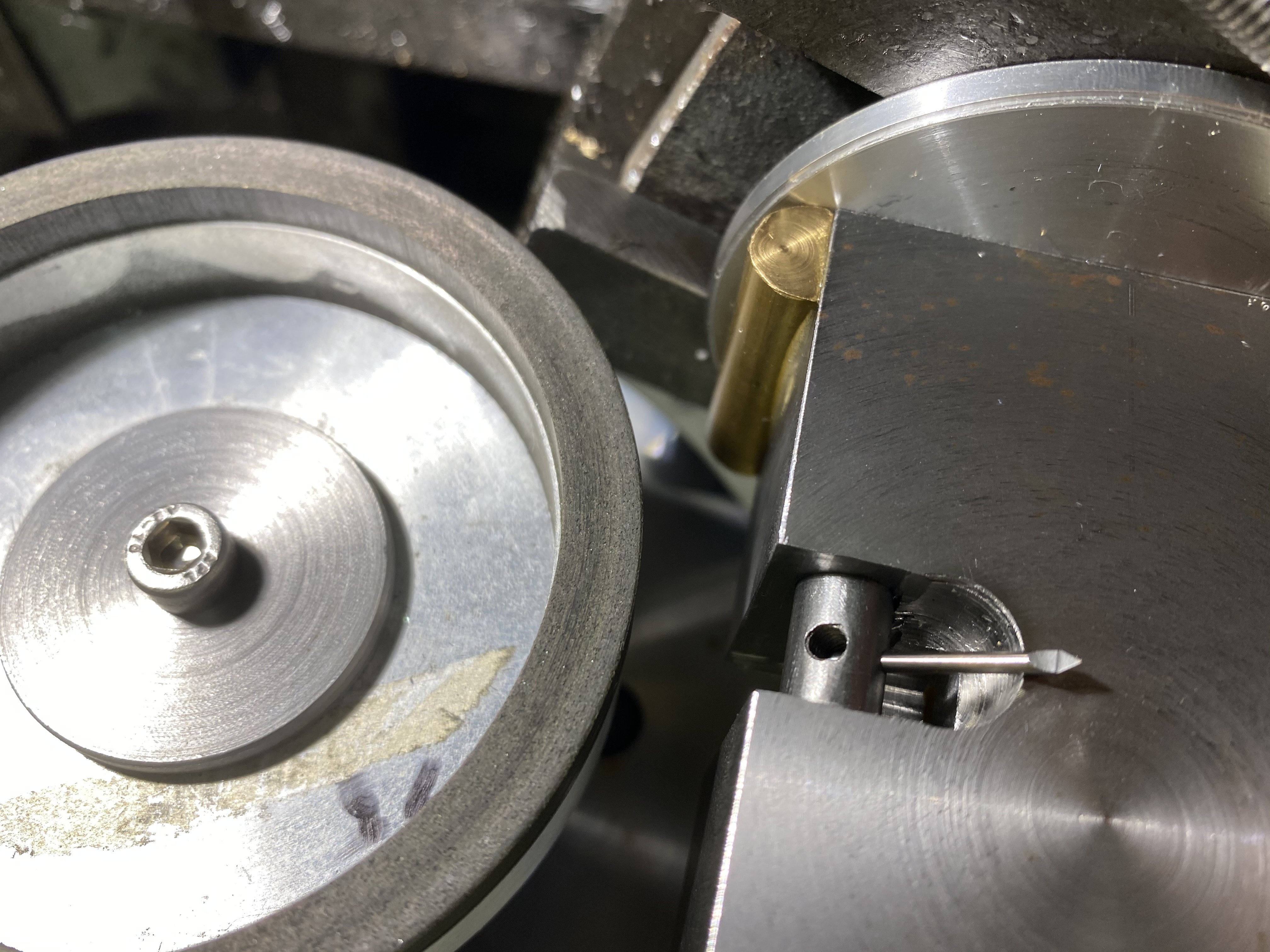

Step 5: Roughing the first side.

Step 6: Roughing the second side.

Step 7. Polishing the first side.

Step 8. Polishing the second side.

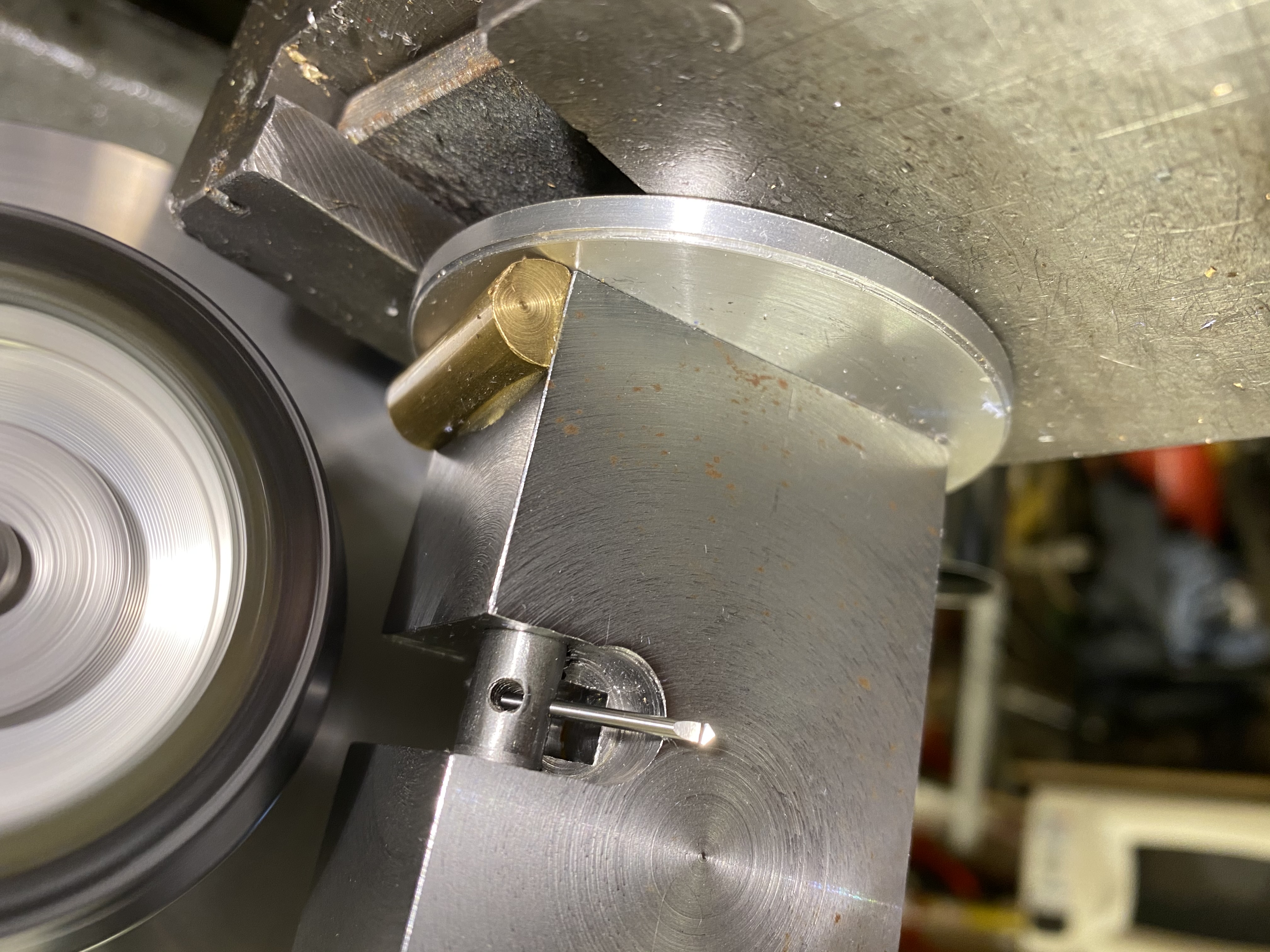

Step 9. Deburring the cutting face (Colchester Bantam lathe).

.

.

Step 10. Polishing the cutting face.

.

.

Upside... you can make anything. Downside... takes about 10X as long to do as with a jig. Just the visual inspections are time consuming.

Each cutting op needs 3 inspections per cut. One to check its roughly right. A second to check its going right & a third to see that it completed right. And that's if everything goes as planned. That's 24 visual inspections per needle.

Still... the results compared to what I was doing are in a totally different league.

I've got a lapping disk that I could charge with sub micron diamond paste for 'super finishing' but no point doing that till I know these actually work.

Just because they look good means nothing. They could look good & the geometry could be crap & they might not work at all.

We shall see I guess.