let me introduce quickly: Ma Name is Hannes, we founded this year our Company AUSTROVINYL from Zero. Cutting, electro-plating, pressing -->having all in "one house" is the goal!

Now we're proud owners of a brand new Pheenix Alpha press and we started testpressing 3 weeks ago.

more pics etc.. http://www.facebook.com/austrovinyl http://www.austrovinyl.at

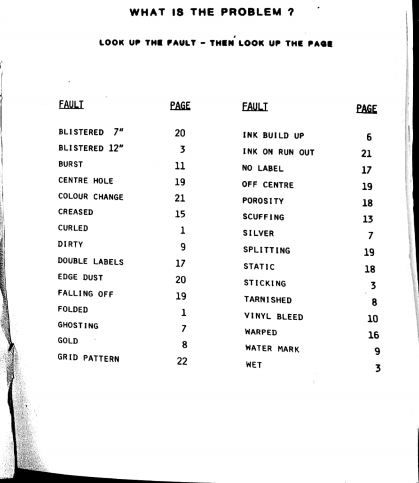

Here is the Problem:

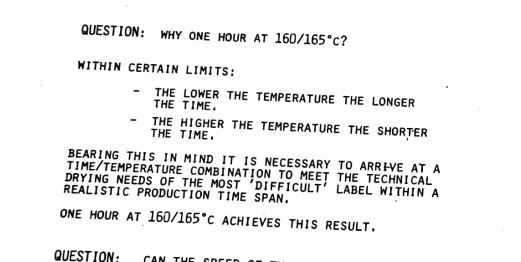

Eventhough we dry the labels for hours in a laboratory oven with 85 degrees, the color of the labels sticks on the stampers! (..it takes me allways 20 minutes to clean them..

Pressing with White Labels is no Problem at all.. -nice, smooth results!

We tried labels from a different printing company aswell, -same problem!

I'm very thankful for every tip and trick from you guys!!

P.S.: This forum is great, I love it!