Seems I really like to tinker.... I acquired this lathe from Alan a while ago (sameal), transplanting it from Milwaukee to rural Michigan. Here's the original thread on this particular lathe - http://lathetrolls.com/viewtopic.php?f=1&t=6143&p=38779&hilit=name+that+lathe#p38682

New pictures:

Platter and overhead

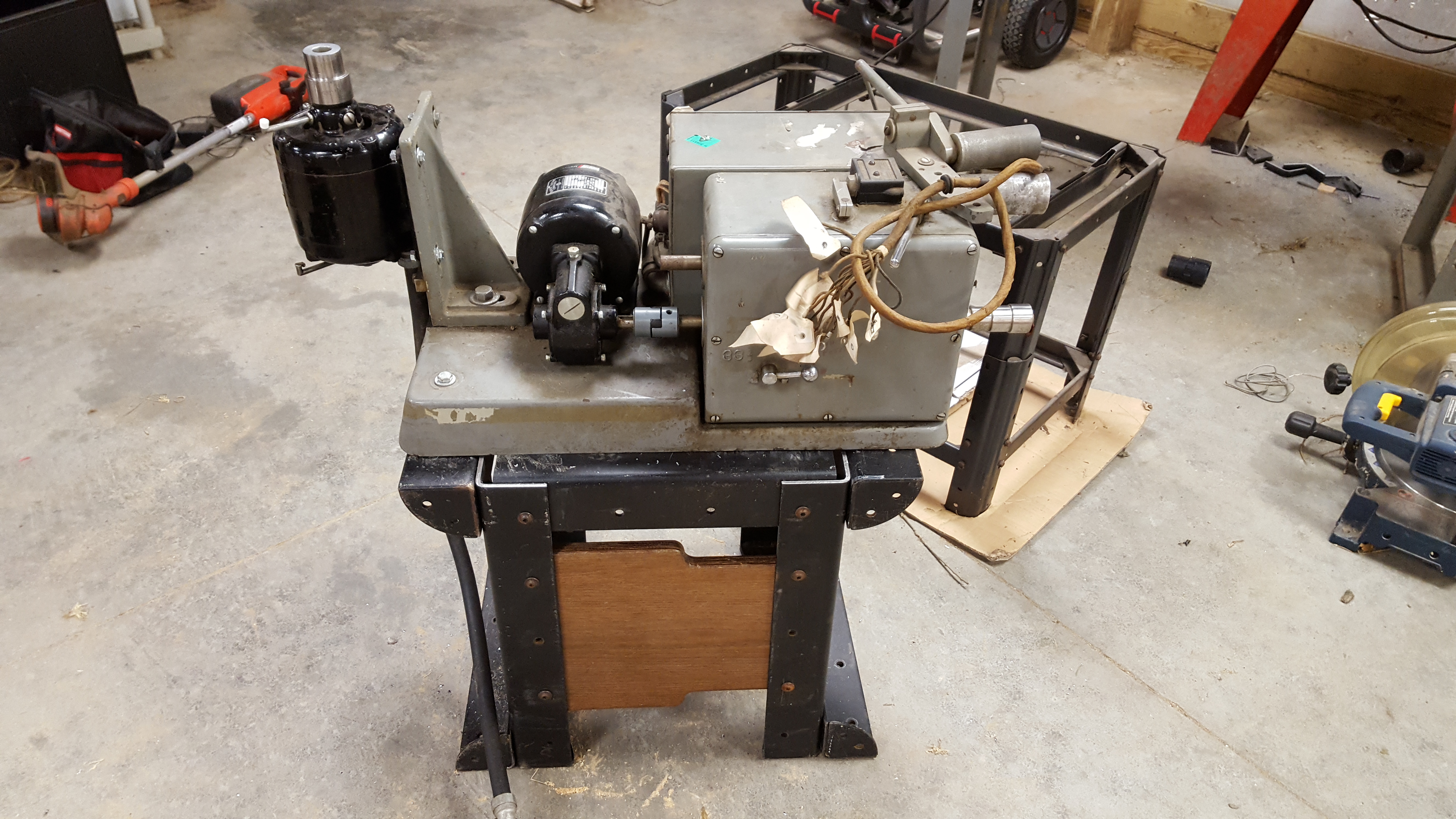

Motors/gearbox

Speed shifting on gearbox

Relays in gearbox

Relay connectors on lathe, connected to control buttons

Control buttons

Underside - Pulleys

Stepped pulley attached to feedscrew, mates to stepped pulley on gearbox

Cutterhead lift mechanism, automated system

Half-nut underneath sled

Bare base

Cutterhead manual lift/lower mechanism, tension spring

Turntable Drive Motor

Underneath Platter - A.S.B 6.27.57 (the only date or resemblance to information on this lathe)

Quite an interesting beast. It uses a series of relays and micro switches to a automate the various processes. From what I can gather and others agree, it's a single LPI lathe that uses a gearbox with a stepped pulley off the gearbox and feedscrew to control the speed for in/out spirals as well as in-between track spirals. I don't see any sort of controls for changing the LPI itself. The platter motor has a pulley on the motor shaft that goes to a drive pulley that then is attached to the platter pulley. The platter itself is 50lbs of solid brass.